The unique features of our Universal Feeders make them the only choice for your grain feeding needs.

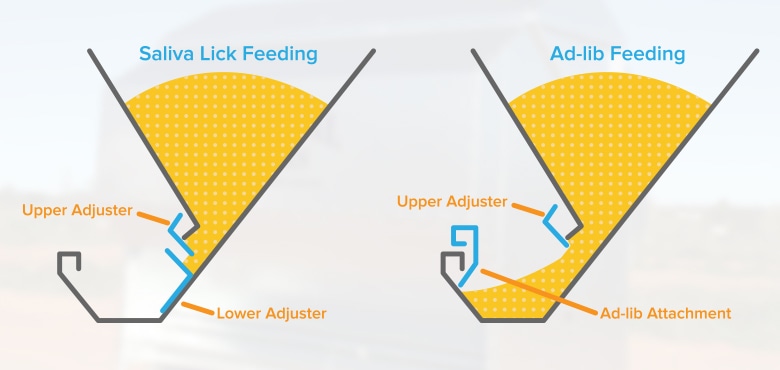

The saliva lick feeding system of Universal Feeders requires livestock to utilize saliva to draw feed out from between two plates which Universal Feeders call adjusters

The upper adjuster controls the depth of the grain whilst the lower adjuster controls the width of the grain available for consumption

As the livestocks’ tongue goes into the the groove, the feed that sticks to the tongue is the ration they can consume. The saliva decreases with progressive licks until the animal is unable to obtain any more feed

Livestock will leave the feeder once they are unable to obtain more feed, enabling other animals to have their turn

The age and breed of the livestock are both factors which affect the calibration of the Feeder. For this reason Universal Feeders supply a guide for initial calibration however the most accurate rates will be achieved through self calibration

HOW TO USE

To enable the ability to monitor feeding rates two adjusters are used.

The upper adjuster allows the feed being used to be placed into the tray at the desired height. This enables the producer to dictate the depth of grain the tongue can reach each time.

The lower adjuster is used to wipe the feed off the tongue of the animal. The closer it is set the more grain that will be removed from the tongue as it retracts from the feeder.

lower adjusterIt is important to remember that the grain or pellets will dry the saliva from the tongue so these settings are crucial to achieve the optimum benefits. In certain circumstance a lower rate may be required or the grain quality may be poor. For this reason Universal Feeders have a patented design apparatus that can be fitted to the feeder to give another means to regulate the feed intake.

As the concept is based on saliva, it is important for the feeder to be placed strategically so the water source for the animals is not too accessible. This way they are unable to drink and go back to the feeder with the saliva being replenished.

ADVANTAGES

- Ability to control intake of sheep and cattle without daily monitoring – can ration feed to the requirements as needed.

- Patended tongue controller

- Fill large quantities of feed into feeder at one time.

- Access of grain to animals over a 24hour period rather than at specified times.

- Less pressure on animals feeding quickly due to feed running out.

- Allows smaller animals time at the feeder after the more forthright ones leave.

- Ability to skid tow feeders

- Checker plate on the base to stop disturbance of soil by animals’ hooves, making the feeder safer and more stable.

- Supports welded to the frame to enable feeder to be lifted with grain in using pallet forks used.

- Hot dipped galvanised frame to help in rust prevention.

- 275gms/Zn per m2 galvanised sheets used.

- Stainless steel (201) used to secure adjusters.

- Steel framed hot dipped galvanised lid hinges.

- Full length lid allowing easy filling.

- 3 inspection windows.

- The ability to buy a saliva lick feeder with strength.

ISSUES SOLVED BY UNIVERSAL FEEDERS

| Problem | Solution |

|---|---|

Animals sliding their tongue to flick the grain out rather than licking |

Patented tongue controller |

Ground eroding from support area of the feeder |

3mm checker plate over the skids |

Hard to shift |

Welded frame designed for skid towing can be shifted with some grain in feeder. |

Hard to lift with grain in feeder |

Extra piece of 70 x 50 x 3mm RHS to allow standard forks to lift the feeder safely. |

Rusting areas of the frame |

Hot-dipping of the frame after welding |

Feeder twisting on uneven ground |

Specially designed trussed frame |

Damage to feeder at eating area |

2mm sheet steel above adjusters |

Hard to see inside feeder |

3 strategically located windows |

Hard to fill |

Full length lid allows ease of filling |

Hard to change to ad-lib feeding |

Specially designed attachment to change to ad-lib feeder. |